cages

Cages are an essential part of bearing performance. The cage separates the balls to prevent them coming into contact and thus ensuring an even load distribution within the bearing. Depending on the application and performance requirements, special materials and cage designs are necessary. Friction, speed and acceleration values as well as temperature conditions will impact the decision on specific cage design.

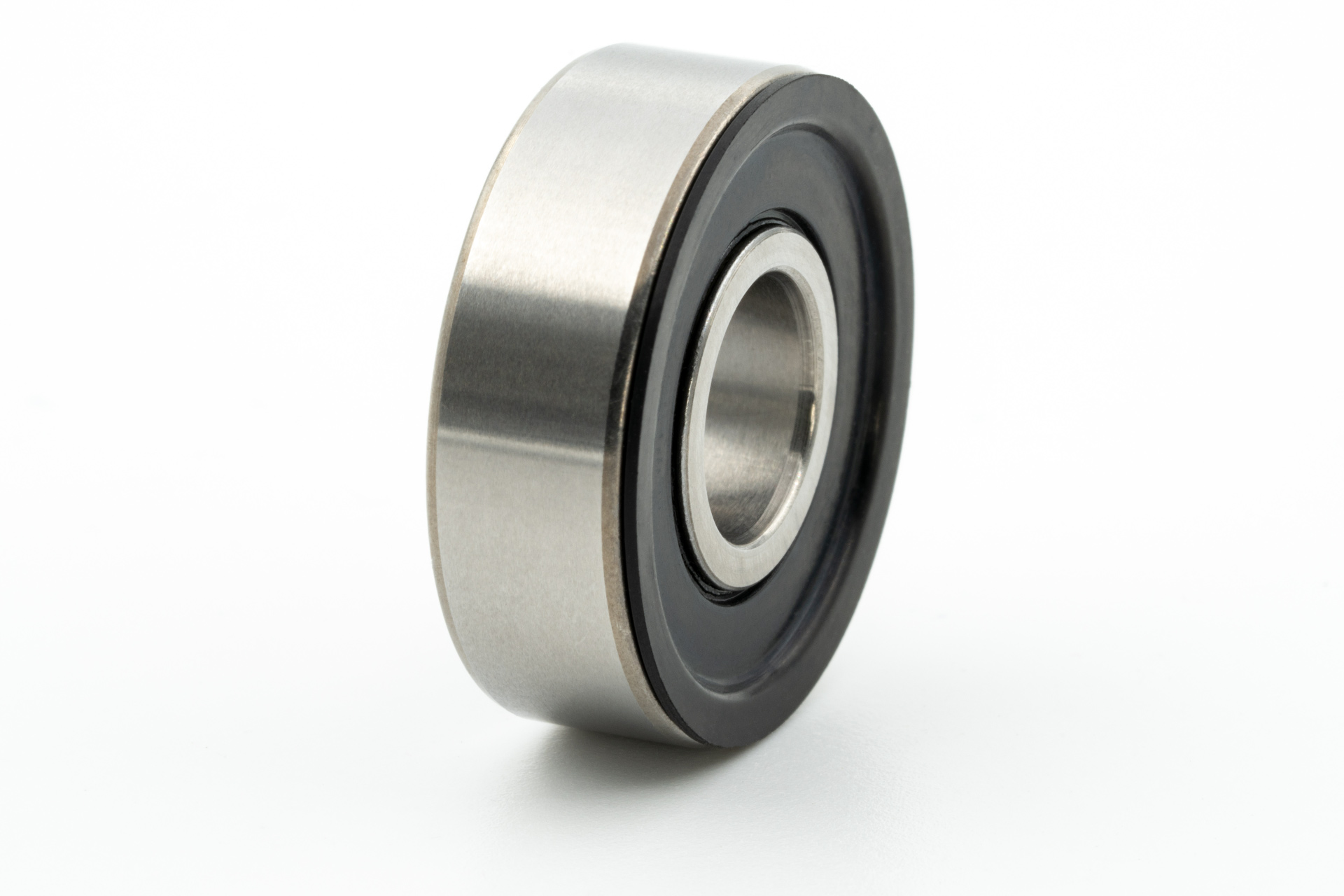

seals

BTC offers several sealing types, all designed to offer the maximum protection against dirt and contamination ingress and lubricant leakage and ensure the best possible performance of the bearings.

Seals are specified depending on the application, and come in a wide range of sizes and materials.

All BTC seals have been optimised to offer low friction and longer service life. They are particularly suited to applications which are contaminant heavy, such as the construction industry and food and beverage production.

wavespring washers & shims

Wave spring washers from BTC Engineering are manufactured in a distinctive wave shape, which produces spring pressure under compression. They are generally used for axial preloading of roller bearings, in particular small and miniature bearings. Wave spring washers are suitable for a range bearing applications, including shafts and housings, heavy industry and gearboxes. They can be produced in a variety of diameters, thicknesses and materials, including corrosion resistant steel.

Shims are often used as a cost-effective way to balance axial manufacturing tolerances. They can also reduce wear on the faces between mating components by acting as a sacrificial component.